In vacuum forming heated clamps are used to clamp the hot rubbery sheet.

Most flexible plastic sheet thermoforming.

Free shipping on your first order shipped by amazon.

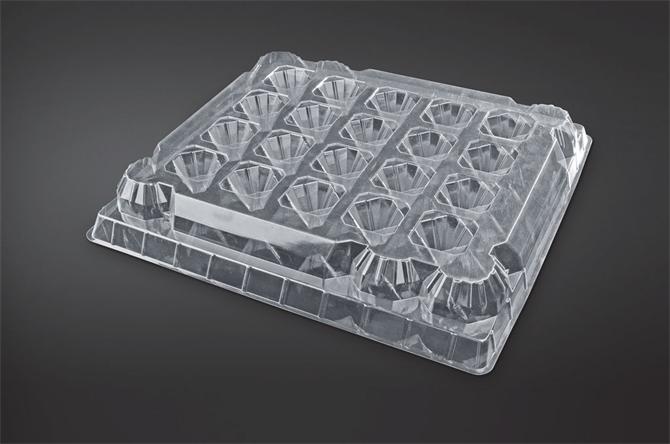

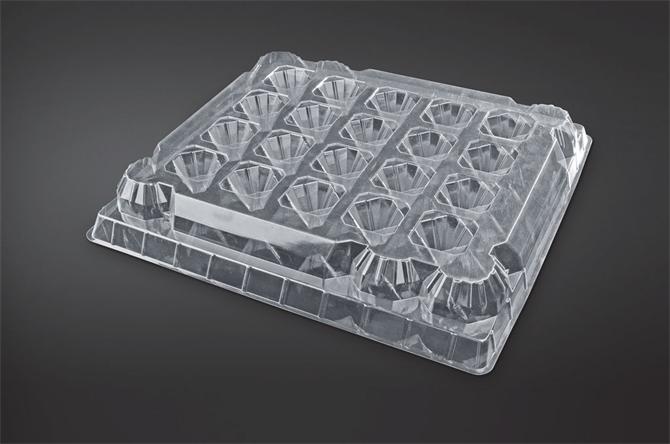

Thermoforming is a process of heating a thermoplastic sheet to its softening point.

The most common methods to get the sheet to conform to its final shape are vacuum forming pressure forming and mechanical forming.

Many plastic sheet materials can be shaped by thermoforming.

Dental lab 20pcs hard vacuum forming plastic sheets thermoforming plastic sheet splint material 1 0mm.

The sheet edges are then sealed against the rim of a female mold and vacuum is applied from the mold side.

Styrene thermoform plastic sheets high impact styrene is an inexpensive thermoform plastic that is easy to work with and produces excellent vacuum forming results making styrene the perfect beginner plastic for folks who are new to vacuum forming.

Amorphous plastics like abs and polycarbonate generally have wide processing windows and good melt strength making them easy to thermoform.

Then it cools into the desired shape.

In all cases the first step is to heat up a two dimensional plastic film or sheet and then under a vacuum or with compressed air press it against the contours of a mould.

Some plastics like hdpe and pp have narrower processing windows and lower melt strength which make them more difficult but not impossible to thermoform.

4 2 out of 5 stars 15.

Get it as soon as thu sep 10.

The edge is the first part to cool down and will be the thickest.

Thermoforming is a highly economical process for the million fold manufacture of products such as the previously mentioned beaker lids as well as blister packs and trays.